The PC Series 5-Axis CNC Machine is an economical and practical solution designed for trimming and drilling complex curved composite products.

With a table-moving structure and RTCP (Rotational Tool Center Point) function, this machine is widely used as a 5-axis CNC router, CNC cutting machine, or 5-axis CNC machine in composite product finishing applications.

It is especially suitable for vacuum-formed composite parts, where accurate edge trimming and hole drilling on complex surfaces are required, while keeping equipment investment under control.

Key Features of the economical 5-Axis CNC Solution

1. Designed as a cost-effective 5-axis CNC router, the PC Series focuses on essential functions required for composite trimming and drilling, making it an ideal entry-level solution.

2. The table-moving and fixed gantry design ensures stable accuracy, compact footprint, and reliable performance for composite material processing.

3. Equipped with a SYNTEC 5-axis CNC system, the machine supports true RTCP functionality, enabling accurate tool orientation control and easier CAM programming for complex curved surfaces.

4. A standard 6 kW air-cooled spindle with high speed 18000rpm, which provides sufficient power for composite materials such as ABS, PVC and reinforced plastics, ensuring smooth cutting and clean edges.

5. The machine is specifically tuned for high-efficiency trimming, edge finishing and hole drilling of formed composite products rather than heavy cutting.

6. Optional disc-type tool magazine and automatic tool change spindle. These options allow flexible configuration based on production needs and budget.

Technical Parameter of PC Series 5-axis cnc machine:

| Project | Item | Value |

| Spindle | Spindle Type | Italy HSD Clamp Spindle |

| Spindle Power | 6KW | |

| Max. Speed | 18000rpm | |

| Collet Type | ER32 | |

| Cooling Type | Air Cooling | |

| Control System | Taiwan Syntecv Controllor with RTCP | Optional: China HNC System |

| Taiwan Syntec Servo System | Match with controllor | |

| Speed | Max. Working Speed (XYZ /min) | 20m/20m/8m |

| Max. Rapid Speed (XYZ /min) | 35m/35m/10m | |

| Accuracy | Positioning Accuracy (XYZ mm/m) | 0.15/0.15/0.1mm |

| Repeatabiliy Accuracy (XYZ mm/m) | 0.1/0.1/0.08mm | |

| Others | Air Pressure | 0.6-0.8 kgf/cm2 |

| Total Power | 324KVA | |

| Voltage | 220V 3P / 380V 3P |

Applications of the PC Series 5-Axis CNC Router:

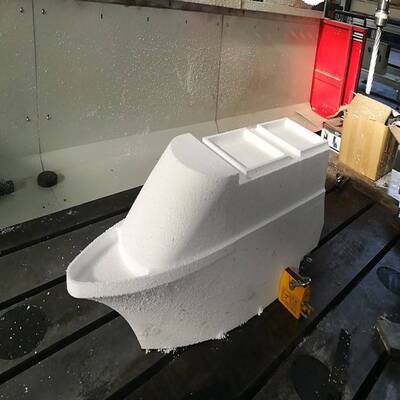

Be mainly used for trimming, cutting and drilling of formed composite products, including but not limited to:

1. PVC bathtub trimming and drilling.

2. Safety helmet shell trimming.

3. Luggage and suitcase shell edge finishing.

4. ABS / PVC / composite housings.

5. Vacuum-formed composite parts.

6. General composite product post-processing.

Thanks to the RTCP function, the machine is ideal for industries requiring high-quality surface finish on complex 3D shapes, while simplifying programming and operation.

Why Choose PC Series 5-Axis CNC Machine?

1. The PC Series offers a perfect balance between functionality and cost, making it a popular choice for manufacturers focused on composite product finishing rather than heavy machining.

2. Whether you call it a 5-axis CNC router, CNC cutting machine, or 5-axis CNC machine, the PC Series delivers reliable performance, easy operation and stable accuracy for composite trimming applications.

FAQ – PC Series 5-Axis CNC Router

Q1: What materials can the PC Series machine process?

The PC Series is designed mainly for composite materials, such as ABS, PVC, fiberglass and vacuum-formed plastic products. It is ideal for trimming and drilling finished composite parts.

Q2: Is this machine suitable for metal cutting?

No. The PC Series is not intended for metal machining. It is optimized for composite trimming and drilling, focusing on efficiency and surface quality rather than heavy cutting.

Q3: Why is RTCP important for composite trimming?

RTCP allows the tool tip to remain accurate during multi-axis movements, which is essential for complex curved surfaces. It also makes CAM programming and operation much easier.

Q4: What industries commonly use this 5-axis CNC router?

Typical industries include sanitary ware manufacturing, luggage and case manufacturing, helmet production, composite housings, and vacuum-formed product processing.

Q5: Is this machine suitable for beginners?

Yes. The PC Series is an entry-level 5-axis CNC machine with simplified configuration and user-friendly operation, making it suitable for users new to 5-axis composite processing.