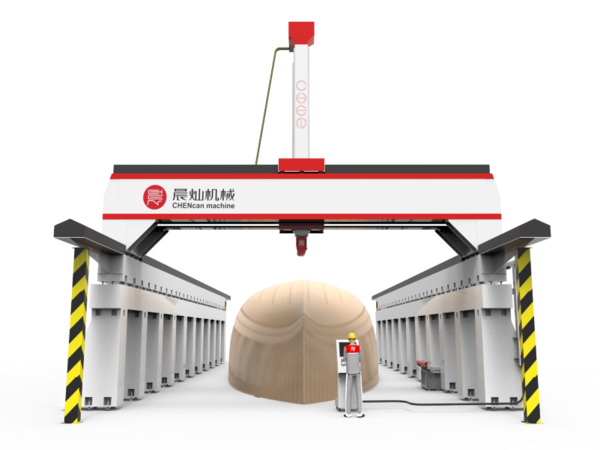

The Large-Scale 5-Axis Gantry Moving Machining Center is a fully customized 5-axis CNC router designed for extra-large, high-precision non-metal machining applications.

Compared with standard gantry 5-axis machines, this model features significantly larger working dimensions and is engineered specifically for oversized complex models and molds.

It is widely referred to as a large 5-axis CNC router, especially in industries such as wind energy, marine manufacturing, and large architectural modeling.

With true 5-axis simultaneous machining capability, the machine enables one-time forming of ultra-large and complex geometries, delivering excellent accuracy and surface finish.

Key Features of Extra-Large 5-Axis Gantry Moving Structure:

1. The gantry moving design provides: Superior rigidity for ultra-large workpieces, Excellent long-term accuracy retention, Stable performance during long machining cycles. This structure is ideal for large molds, plugs, and full-scale models.

2. Fully Customized Machine Configuration: This model is a 100% customized solution, with machine size, configuration, and functions tailored to specific project requirements, ensuring optimal performance for extra-large applications.

3. High-Torque Motorized Spindle: Equipped with HKS63F or HKS63A high-torque motorized spindle, featuring: High torque output for large cutters, Smooth and consistent surface finish, Stable performance for long-time continuous machining.

4. Ideal for deep cutting and high-quality surface processing of non-metal materials.

5. Hybrid Drive System for Large-Scale Accuracy: Z-axis: High-precision ball screw transmission for vertical accuracy, X & Y axes: Rack and pinion drive system for high speed and long travel. This combination ensures both speed and precision on extra-large machines.

6. Backlash Elimination Option: According to different accuracy requirements, backlash elimination systems can be optionally configured to: Minimize positioning errors, Improve repeatability, Maximize accuracy on large molds and long-axis travel.

7. True 5-Axis Machining with RTP Function: Programming easier, Operation simpler, Complex machining more reliable, Large-Capacity Linear Tool Magazine

8. It excels in surface machining, contouring, trimming, and drilling of extra-large components.

Technical Specification of 5-Axis CNC Center:

| Project | Item | Value |

| Spindle | Spindle Type | Italy Imported HSK 63F Spindle |

| Spindle Power | 20KW | |

| Max. Speed | 24000rpm | |

| Max. Tool Diameter | 32mm | |

| Max. Tool Length | 300mm | |

| Control System | China HNC CNC Controllor with RTCP | Optional: Syntec / Siemens |

| China HNC Servo System | Match with controllor | |

| Speed | Max. Working Speed (XYZ /min) | 35m/35m/15m |

| Max. Rapid Speed (XYZ /min) | 60m/60m/20m | |

| Accuracy | Positioning Accuracy (XYZ mm/m) | 0.05/0.05/0.03mm |

| Repeatabiliy Accuracy (XYZ mm/m) | 0.03/0.03/0.025mm | |

| Others | Air Pressure | 0.6-0.8 kgf/cm2 |

| Total Power | 58KVA | |

| Voltage | 220V 3P / 380V 3P |

Why Choose This Large-Scale 5-Axis CNC Router?

1. Extra-large working size with full customization.

2. Gantry moving structure for stable long-term accuracy.

3. High-torque motorized spindle for large cutters.

4. Hybrid drive system for speed and precision.

5. Ideal for wind energy, marine, and large architectural applications.

6. This machine is the ultimate solution for manufacturers requiring a custom-built, large-format 5-axis CNC router for complex non-metal machining.

FAQ – Large-Scale 5-Axis CNC Router

Q1: Is this a standard machine or a customized solution?

This machine is a fully customized 5-axis machining center, designed according to specific size, accuracy, and application requirements.

Q2: What materials can this large 5-axis CNC router machine?

It is mainly designed for non-metal materials, such as: Foam, MDF and wood, Resin, Plastics, Composite materials. It is especially suitable for large models and plugs.

Q3: What industries typically use this extra-large 5-axis CNC router?

Common industries include: Wind energy (blade models and molds), Yacht and shipbuilding (plug manufacturing), Large-scale Architecture and construction modeling, Industrial design and large-scale mock-ups, Precision casting patterns for large components, Oversized composite structures.

Q4: Why is rack and pinion used on X and Y axes?

For extra-large machines, rack and pinion drives offer: Higher travel speed, Better suitability for long stroke axes, Stable performance over large working areas. Combined with a ball screw on Z-axis, it ensures both accuracy and efficiency.

Q5: What is the benefit of backlash elimination?

Backlash elimination helps: Improve positioning accuracy, Enhance repeatability, Maintain precision on large molds and long-distance movements. This is critical for large-scale high-precision machining.

Q6: Can this machine be customized further?

Yes. Customization options include: Working size, pindle type, Drive system configuration, Control system and so on.