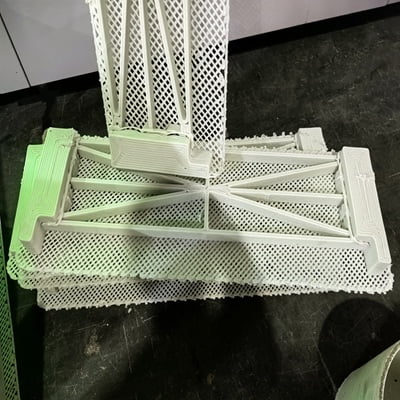

The DFL Large-Scale Industrial Pellet 3D Printer is a heavy-duty industrial pellet-based additive manufacturing system designed specifically for large-size and high-efficiency printing applications.

With a gantry moving structure, this machine provides a large working envelope, stable motion control, and excellent accuracy for oversized parts.

Compared with DF series pellet 3D printers, this series 3d printer is equipped with high-capacity extrusion heads (12–25 kg/h) and large-diameter nozzles (8–20 mm), making it ideal for fast deposition and large-format printing.

Key Featuresof Gantry Moving Structure for Large-Scale Printing

1. Adopt gantry moving design: ensures large printable size, stable motion for long-time printing, high positioning accuracy for oversized components. This structure is ideal for large-format industrial additive manufacturing.

2. High-Capacity Pellet Extrusion System: equipped with 12–25 kg/h high-output extrusion heads, with fast material deposition, shorter printing time for large parts and stable extrusion during continuous operation.

3. Large-Diameter Nozzle Configuration, supports 8–20 mm nozzle diameters which allowing: high-efficiency printing, strong layer bonding, optimized performance for large-scale components. This setup is especially suitable for functional and structural parts.

4. Using pellet materials instead of filament offers: lower material cost, wider material compatibility, easier use of recycled and custom compounds.

5. Hybrid Manufacturing Compatibility: Chencan 3d printer can be combined with CNC machining centers, which enables additive + subtractive hybrid manufacturing, suitable for industries requiring both high efficiency and high surface accuracy.

Technical Specification of DFL Series Pellet 3D Printer:

| Project | Item | Value / Note |

| Screw Extrusion System | Screw Diameter | 20mm |

| Max. Heating Temperature | 350 degrees | |

| Raw Materials | Pellet | |

| Extrusion Motor | Servo | |

| Max. Output | 12Kgs | |

| Control System | CHENcan CNC Controllor | With USB / WIFI / Elthernet |

| Slicing Software | Cura | Optional: Orca / Simplify 3D |

| File Formats | 3d Drawing | STL / OBJ / 3MF |

| Nozzle Diameter | 2mm-8mm | 2mm-20mm for 25KGS Output Head |

| Repeatabiliy Accuracy | XYZ | +/- 0.15mm |

| Working Speed | XY | 200mm/s |

| Z | 10mm/s | |

| Automatic Feeding Sytem | Yes | With 100KGS Hopper Dryer |

| Others | Air Pressure | 0.6-0.8 kgf/cm2 |

| Total Power | 4KVA | |

| Voltage | 220V 3P / 380V 3P |

Key Applications of large-format pellet 3D printer:

1. Large industrial prototypes.

2. Mold and pattern manufacturing.

3. Foundry patterns and tooling.

4. Architectural components and structures.

5. Boat, yacht and marine parts.

6. Large sculptures and art installations.

7. When integrated with CNC machining centers or robotic systems, it can support hybrid manufacturing workflows, expanding its application range across multiple industries.

Materials Compatibility of this industrial pellet 3D printer

Supports a wide range of thermoplastic pellet materials, including: ABS, PLA, PETG, PP, TPU, Fiber-reinforced pellets, Recycled plastic pellets.

Why Choose CHENcan Large-Scale Pellet 3D Printer?

1. Designed specifically for large-size industrial printing

2. High extrusion output for maximum efficiency

3. Gantry structure for stability and accuracy

4. Lower material cost with pellet-based system

5. Ideal for hybrid manufacturing workflows

CHENcan DFL series pellet 3d printer is an excellent choice for manufacturers seeking a large-format industrial pellet 3D printing solution.

FAQ – Large-Scale Industrial Pellet 3D Printer

Q1: What is the advantage of pellet 3D printing compared to filament printing?

Pellet 3D printing offers lower material cost, higher extrusion output, and wider material choices, making it ideal for large-scale industrial applications.

Q2: What extrusion capacity does this machine support?

The printer supports 12–25 kg/h extrusion heads, suitable for high-speed large-format printing.

Q3: What nozzle sizes are available?

The system supports 8–20 mm diameter nozzles, optimized for fast deposition and strong layer bonding.

Q4: Is this printer suitable for large-size parts?

Yes. This machine is specifically designed for large-format and oversized parts, such as molds, patterns, and structural components.

Q5: Can this pellet 3D printer be combined with CNC machining?

Yes. It can be integrated with CNC machines or robotic systems to create hybrid additive–subtractive manufacturing solutions.

Q6: What industries commonly use this large pellet 3D printer?

Typical industries include:Mold and pattern making, Foundry tooling Architecture and construction, Marine and boat manufacturing, Sculpture and art…

Q7: Can recycled materials be used?

Yes. The pellet-based system allows the use of recycled and custom-compounded pellets, reducing material cost and supporting sustainable manufacturing.

Q8: Is this machine suitable for continuous industrial operation?

Yes. The printer is designed for industrial-grade, long-time continuous printing, ensuring stable performance and reliability.